Industrial Ventilation Fans • Axial & Radial Solutions

ALFAN brand industrial ventilation systems offer high airflow, quiet operation, and long-lasting use in all enclosed spaces, from poultry houses and cattle barns to greenhouses and factories. We provide end-to-end ventilation solutions with 560–1270 mm axial fans, radial fans, chimney, roof, rotary, and greenhouse fans.

Reliable Ventilation on an Industrial Scale

ALFAN industrial ventilation fans are high-performance axial and radial fan solutions that have been reliably used for years in poultry farming, cattle operations, mushroom cultivation, greenhouses, factories, workshops, and silo ventilation systems.

Wide Product Range

A wide range of products to suit every diameter and capacity requirement, including 560 (22"), 660 (26"), 760 (30") and 1270 (50") type axial fans; radial fans, chimney, roof, rotary and greenhouse fans.

Three Different Wing Options

High efficiency, low energy consumption, and long service life thanks to the specially curved aluminum, galvanized steel, and stainless steel blades.

Quiet and Efficient Operation

The motor-belt-pulley system, with its cast aluminum pulley and specially designed bearings, ensures quiet operation, low vibration, and a long service life.

Quick Maintenance, Easy Cleaning

Thanks to the ease with which the shutter sets can be removed and reinstalled, cleaning and maintenance of the fan interior can be completed quickly.

Areas of Application

All of our fan families are designed for use in demanding industrial and agricultural environments where air quality, temperature, and humidity are critical.

Poultry Farming

Ventilation and cooling in broiler, laying hen, and turkey poultry houses; control of ammonia, humidity, and heat load; and protection of animal health.

Cattle Barns

High-flow fan solutions for air circulation, cooling in summer, and odor removal in cattle barns.

Greenhouses and Mushroom Facilities

Indoor air circulation, CO₂ control, and humidity balance in mushroom production facilities.

Factories & Silo Systems

Gas, smoke, dust, and odor removal; integrated use with silo ventilation ducts, tunnel ventilation, and chimney solutions.

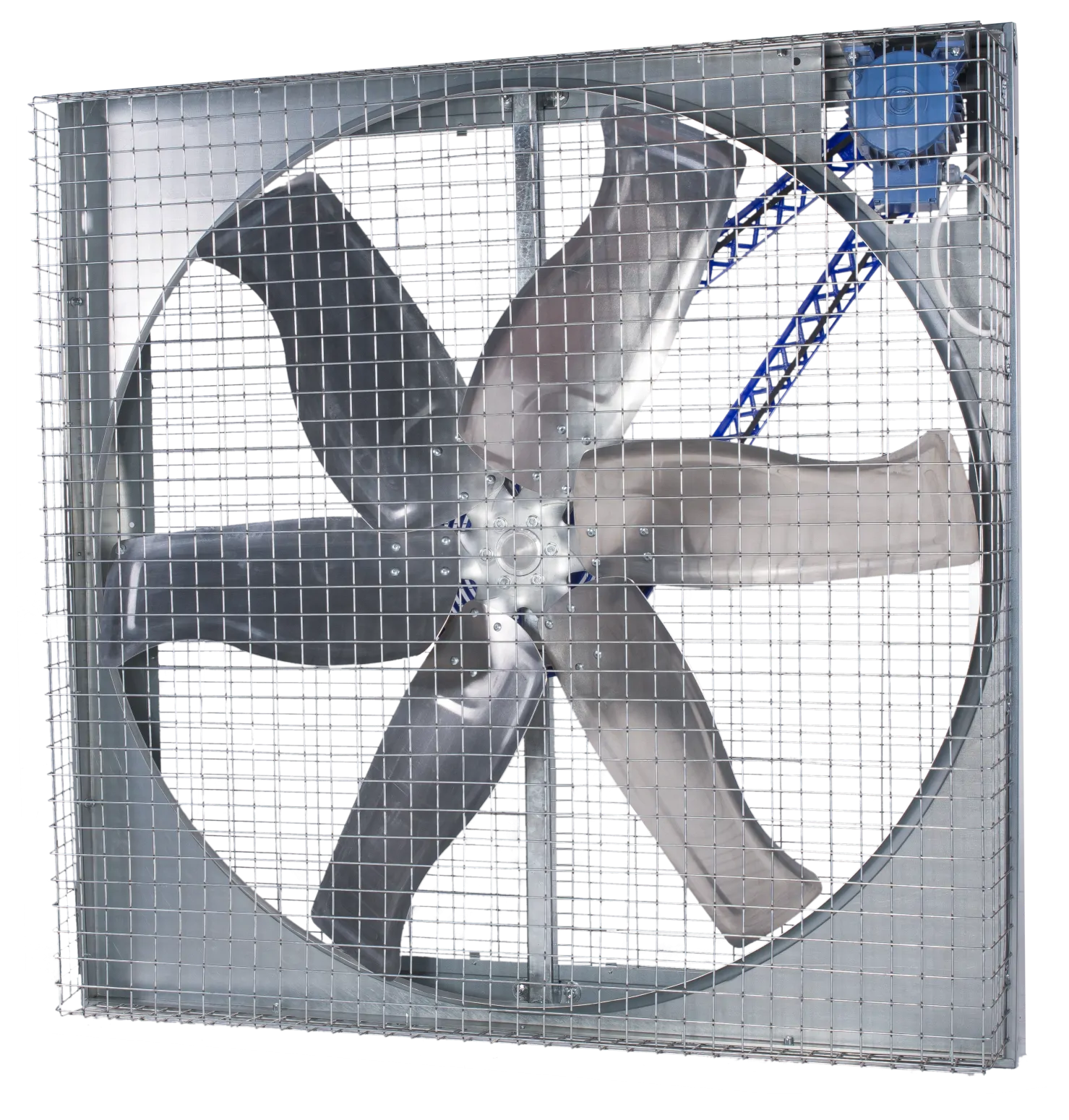

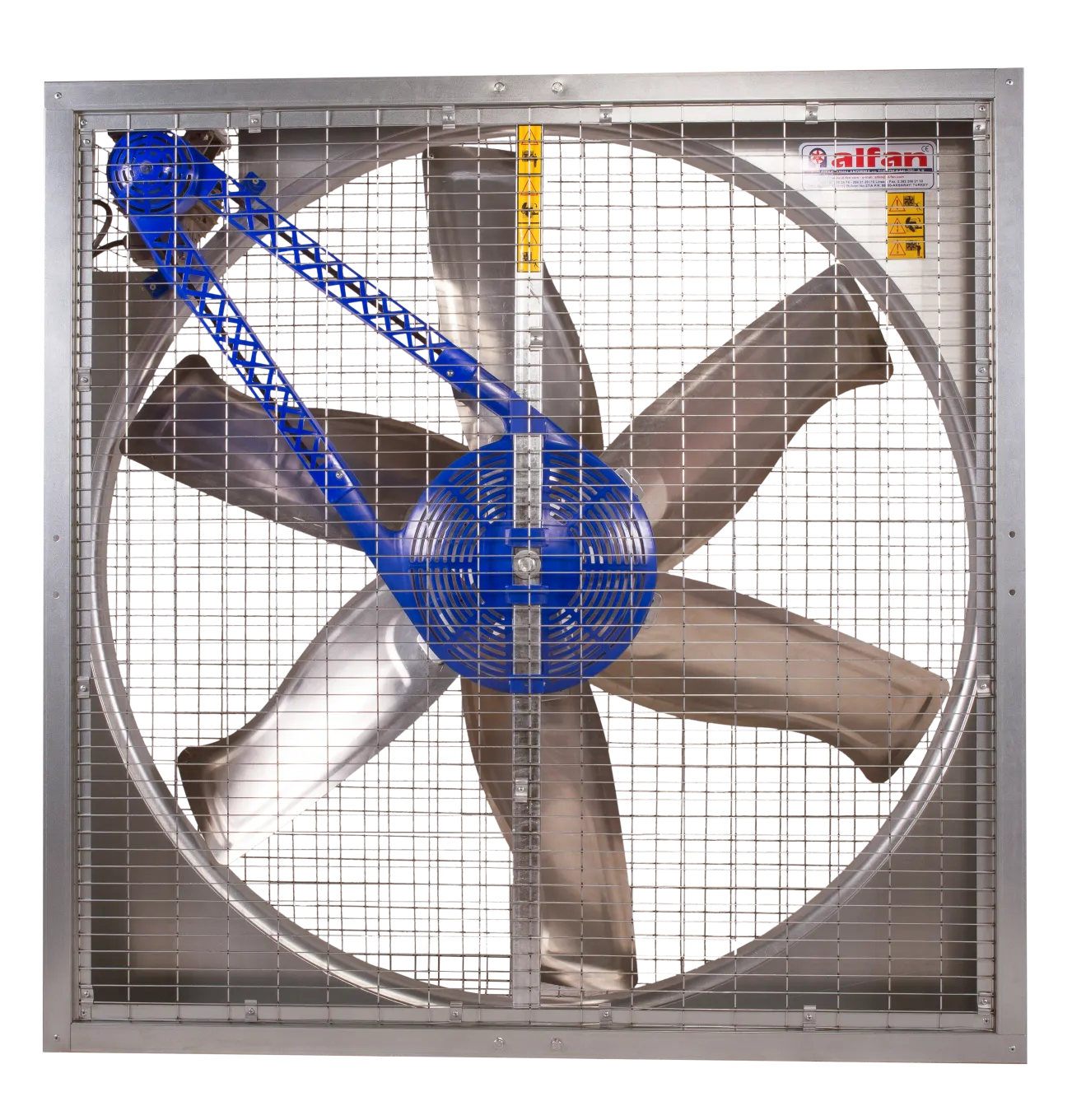

Axial Fan Families

Our 1270, 760, 660, and 560 model axial fans offer the ideal combination for every project with different casing types, louver solutions, and blade materials.

1270 (50") Axial Fans

With options including sequential wire mesh, inverted hood, louvered grille, and narrow casing, it carries the main ventilation load of large-volume poultry houses and barns.

- 1270 Sequential Wire Fans (Aluminum / Stainless Steel / Galvanized)

- 1270 Inverted Hood Fans

- 1270 Louvered Grille Fans

- 1270 Narrow Case Sequential Wire Fans

760 (30") Axial Fans

Flexible solutions for medium-capacity applications with louvered, successive wire, inverted hood, and narrow casing types.

- 760 Louvered Ventilation Fan

- 760 Sequential Wire Fan

- 760 Reverse Hood Fan

- 760 Narrow Case Sequential Wire Fan

660 (26") & 560 (22") Axial Fans

It is used in smaller volume areas, tunnel solutions and auxiliary ventilation points with louvered and sequential wire options.

- 660 Louvered Grille Fan & Sequential Wire Fan

- 560 Louvered Grille Fan & Sequential Wire Fan

Portable & Utility Fans

The 1270, 760, 660, and 560 portable fans are flexible solutions that can be moved to different areas as needed, providing localized cooling and ventilation.

Radial Fans

Designed for high-pressure and long-line air handling needs, our radial fans are used in silo ventilation ducts, tunnel ventilation, and challenging industrial environments.

Use Cases

- Silo ventilation ducts and tunnel systems

- Mobile tunnel ventilation in horizontal grain storage facilities.

- Removal of gas, smoke, dust and harmful particles.

Model Range (Summary)

The RF series radial fans offer different models with motor power ranging from 4 kW to 30 kW, capacities of approximately 7,000 – 21,000 m³/h, and pressure ranges of 152–406 mm.ss.

- RF040 – RF055 – RF075

- RF110 – RF150 – RF185

- RF220 – RF300

Silo Integration

Ventilation ducts embedded in the reinforced concrete silo foundation, combined with perforated galvanized sheet metal cladding and radial fans, allow for the controlled expulsion of moisture, gas, and heat from the product.

Chimney, Roof, Rotary and Greenhouse Fans

Our specialized fan families offer efficient and quiet solutions optimized for various mounting positions and operating conditions.

Chimney Fan

With its round body structure and 61.5 cm inner diameter, this chimney fan offers a corrosion-resistant solution thanks to its polyethylene body and stainless/galvanized metal components, protecting the health of the blades during sudden temperature changes.

Highly efficient chimney ventilation with an air flow rate of approximately 11,720 m³/h.

Roof Fan

The 560 and 660 roof fan types are mounted on the roof and utilize the natural upward tendency of hot and polluted indoor air, providing high airflow with low power consumption.

Galvanized or aluminum sash options, 22" and 26" diameters.

Rotary Type Fans

The 760 and 1270 rotary fan types are designed for applications requiring high airflow and wide area ventilation, and feature a robust housing and blade structure.

Models with capacities ranging from approximately 16,200 to 41,970 m³/h.

Greenhouse Fans

560 and 660 greenhouse fan types improve air circulation inside greenhouses, increasing temperature and humidity homogeneity and supporting plant health.

Galvanized finned, low power consumption solutions.

Design, Materials and Belt Tensioning Technology

All our fans have undergone rigorous engineering scrutiny in terms of mechanical design and material selection to ensure high efficiency, quiet operation, and long service life.

- Aluminum Fins: Made from a special aluminum alloy, 2 mm thick; offering both lightness and high strength.

- Galvanized Steel Wings: 1 mm thick galvanized steel sheet; an economical and durable solution.

- Stainless Steel Blades: Made of 304 or 430 grade stainless steel, 1 mm thick, as per customer request; ensures long service life in aggressive environments.

- All wing types feature a special curvature that increases airflow and reduces energy consumption.

- Shutters that open using centrifugal force and are balanced by weight.

- Louver systems that open with air pressure and suction when the fan is engaged, and close when it stops.

- Thanks to the portable design of the shutter sets, cleaning the inside of the fan is easy.

The motor-belt-pulley system used in ALFAN axial fans is optimized for quiet and efficient operation.

- Long-lasting mechanical structure with cast aluminum pulleys and special bearings.

- A perimeter frame design that allows the shutters to close when the fan stops.

- Special protective wire at the back; ensures safe use and workplace safety.

Adjusting the tension of belts that stretch over time requires extra time and labor with classic systems. With the ALFAN belt tensioning system, this process is completed in 10–15 seconds:

- The nut behind the fan is moved axially using a tensioning tool.

- Once the belt reaches the required tension, it is secured with wing nuts and bolts.

- This prevents the belt from coming loose and avoids loss of fan capacity.

Gallery

For each product family, examine the solutions closely with both product detail photos and visuals showing their application in the field.

Frequently Asked Questions

For general and tunnel ventilation, axial fans of the 1270, 760, 660, and 560 mm are recommended; radial fans for high-pressure and ductwork air handling needs; chimney/roof fans for air extraction from chimneys and roofs; and greenhouse fans for circulation within greenhouses. Capacity calculations will be performed in collaboration with our technical team to select the appropriate fan for your project.

Galvanized steel is preferred for standard and economical solutions; stainless steel for high corrosion resistance and aggressive environments; and aluminum fins for applications requiring lightness and high efficiency. The most suitable fin material is determined by analyzing the operating conditions.

The easy detachability and reattachment of the louvers speeds up internal fan cleaning. Thanks to the belt tensioning system, belt maintenance can be completed in 10-15 seconds. With the periodic maintenance plan, bearing checks, belt checks, and blade cleaning are performed safely.

Detailed airflow (m³/h), pressure (Pa), and power (kW) tables for all models are available in our product catalogs. Once the fan series suitable for your needs is selected, we will share the relevant technical documents with you in PDF format.